Inside the Bugatti factory where engineers spend six months building a £2million Chiron supercar

Pricey motors are polished for two days and exposed to a simulated monsoon to check they are watertight

BUGATTI has opened the doors of its factory to show off the painstaking production of its brand new £2 million car.

The Chiron is the 1,500bhp follow-up to the legendary Bugatti Veyron and can reach speeds of 260 miles per hour.

It is built entirely by hand by engineers and technicians at the company's factory in Molsheim, France, who spend around SIX MONTHS assembling each car.

The production facility is made up of 12 stations, with no conveyor belts or robots used.

At the first station, engineers prepare the powertrain for assembly before installing it on the chassis at station two.

The chassis takes three employees one week to assemble.

After assembling the chassis and powertrain, four wheels are bolted on and the Chiron rolls to the next station where all the operating fluids are filled into the vehicle.

It is at this point the 16-cylinder engine is started for the first time, an "exciting" moment for the production team who then put the Chiron on a rolling dynamometer to ensure the car produces the expected 1,500bhp.

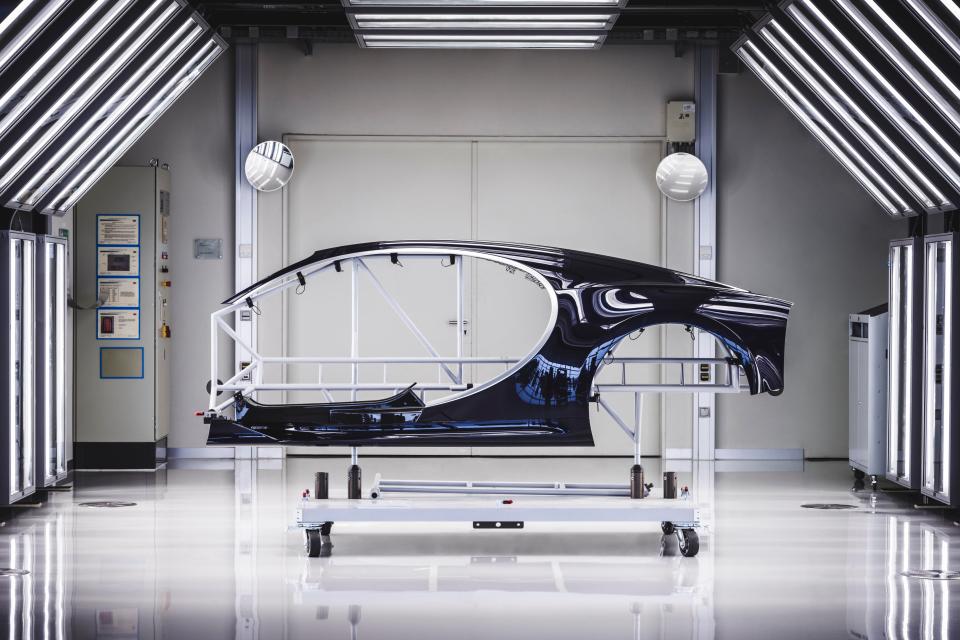

They spend more than two hours testing the car on the rolling road, reaching speeds of up to 124mph. Once it has passed all its tests it is fitted with the carbon fibre body.

And to ensure the car is watertight, the Chiron is the exposed to a monsoon-style rainstorm for 30 minutes.

The Chiron is then taken on a 360 mile-round test drive to Colmar airport when it is driven at speeds of in excess of 150mph before having a final 30 mile test where "dynamic approval" is given.

With the car running as it should, the Chiron is sent to the paintbooth where a team spend two days cleaning and polishing it.

They then take the car to a light tunnel and spent six hours inspecting to see if there are any blemishes in the paintwork. It can then take as much as THREE WEEKS remedying any issues.

The Chiron is then given to Christophe Piochon, head of sales, quality assurance and customer service, who finally signs it off.

Mr Piochon said: "We are building a super sports car. That is quite clear. But it is the way we do it, hand-crafting an individual product for each customer in this very special atmosphere, that makes us unique."

In total, a team of 20 skilled employees assemble the Chiron from 1,800 individual parts in the factory.

Related Stories

They are supported by 17 logistics employees and 15 quality assurance colleagues during the six month process.

The result is the world's most powerful, fastest and luxurious production car. It will do 0-62mph in 2.5 seconds and a top speed in excess of 260mph.

Bugatti plans on delivering the first customer vehicles in the first quarter of 2017 and expects to build up to 70 of the £2 million cars this year.

We pay for your stories! Do you have a story for The Sun Online news team? Email us at [email protected] or call 0207 782 4368